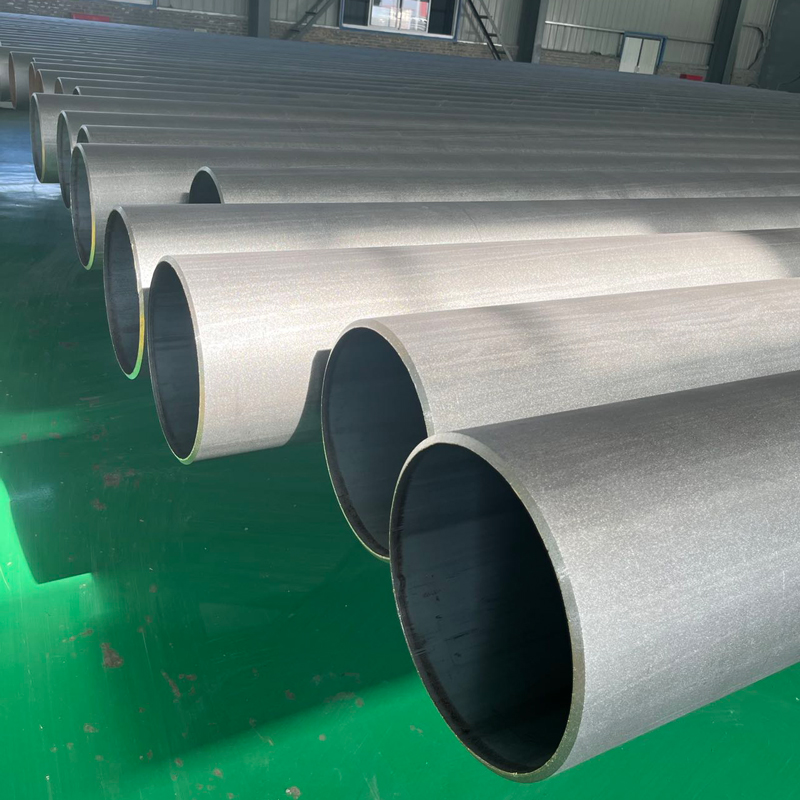

Mkpuchi Epoxy nke a na-ejikọta ọnụ Awwa C213 Standard

Njirimara anụ ahụ nke ihe ntụ ntụ epoxy

Ike ndọda pụrụ iche na 23℃: opekempe 1.2 na opekempe 1.8

Nyocha Sieve: kachasị 2.0

Oge jel na 200 ℃: ihe na-erughị 120s

Nhicha mgbawa na-egbu egbu

A ga-asacha elu ígwè ndị na-enweghị ihe ọ bụla site na iji ihe mkpuchi gbawara agbawa dịka iwu SSPC-SP10/NACE Nke 2 si dị ma ọ gwụla ma onye zụrụ ya kọwara ihe ọzọ. Usoro ihe mkpuchi gbawara agbawa ma ọ bụ omimi profaịlụ ga-adị site na 1.5 ruo 4.0 mil (38 µm ruo 102 µm) dịka iwu ASTM D4417 si dị.

Kpoo ọkụ tupu oge eruo

A ga-ekpocha paịpụ e sachara ọkụ n'oge okpomọkụ na-erughị 260℃, ebe okpomọkụ agaghị emerụ elu paịpụ ahụ.

Ọkpụrụkpụ

A ga-etinye ntụ mkpuchi ahụ n'elu paịpụ a na-ekpo ọkụ n'otu ọkpụrụkpụ nke ihe na-adịghị eru mil 12 (305μm) n'èzí ma ọ bụ n'ime. Oke ọkpụrụkpụ agaghị agafe mil 16 (406μm) ma ọ gwụla ma onye nrụpụta kwadoro ya ma ọ bụ onye na-ere ahịa kwuru.

Nnwale arụmọrụ epoxy nhọrọ

Onye zụrụ ya nwere ike ịkọwapụta nnwale ndị ọzọ iji chọpụta arụmọrụ epoxy. Usoro nnwale ndị a, nke a ga-eme na mgbaaka nnwale paịpụ mmepụta, nwere ike ịkọwapụta:

1. Porosity nke akụkụ obe.

2. Porosity nke njikọ.

3. Nyocha okpomọkụ (DSC).

4. Nsogbu na-adịgide adịgide (ike ịgbanwe).

5. Mmiri na-amịkọrọ mmiri.

6. Mmetụta.

7. Nnwale nkewapụ nke Kathodic.